Welded Diff for Rally?

Posted by cmanreinhart

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

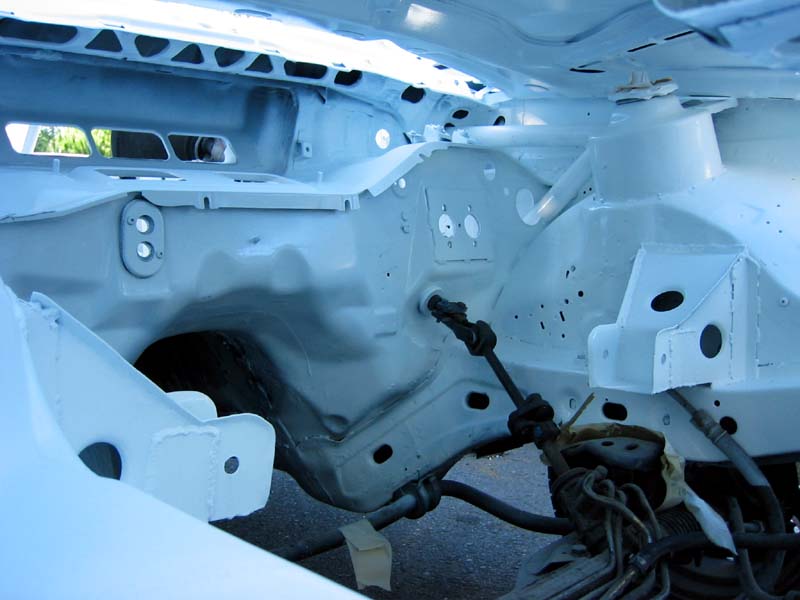

You can of course buy the CV adaptors. You can also buy the raw materials for the whole kit. Other senior projects could be: Sump guard mounts and center support

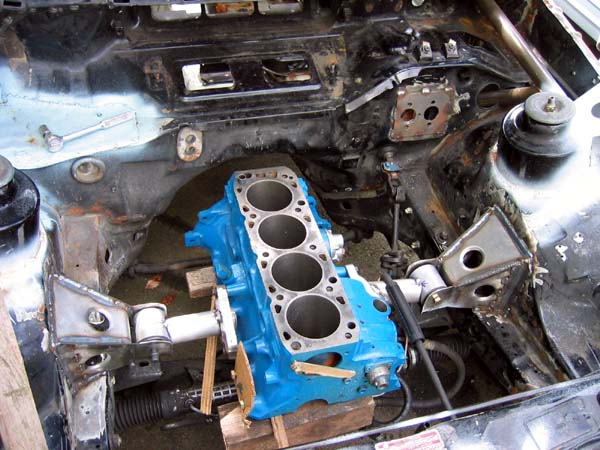

Works behind in blue, copy in front..And that is an exceleent concept to study (strength of materials in compressive loads as a function of height)

Front sump guard mount and combined tow eyelet and integral jacking point: Gearbox crossmember:

Gearbox mount:

Engine mounts so the engine stays put and is not sitting on the poor crossmember:

That is the way most serious rwd cars were done--in one way or another. Serious engine mounts

3 door style rear window:

Pretty simple but huge benefits

Footwell reinforcements:

Seat rails

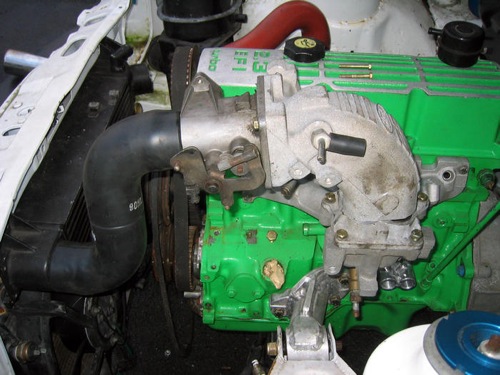

Cut and rotate upper intake to make intercooler plumbing easy

Alternator relocation with clearance so the belt run is optimal, and stock alternator and stock hoses can be used (means getting the alternator fairly close in height to the front crank pulley so belt wraps around a good almost 180 degrees)

These are just some of the projects you could devote some time and energy to. \Copying is learning.. There's an old saying that most throw away Smart people learn from their mistakes.. I say "Smrat-er-er people learn from other people's mistakes" If we shifted the subject from fucking with simple things like cars---where there is virtually no need for "discovering" anything----it's already been done (we just have to find where to get stuff at affordable prices that is good) to something like music think of this: Would you expect--or would your instructors expect---you to begin your studies in music by first composing new symphonies? No, first you learn basics and then learn by playing other people's music until your competent at that, or better.. Thjen---and that may be 6-10-15 years you might think of composing.. Same here. First you can learn more and faster by basically doing an accelerated apprenticeship in copying what the masters do--and by that i mean what Ford did--which they have been polite enough to document for you and publish all kinds of books.. And which i have posted all kinds of photos intended to show details--to make the job of learning a) whatis good, and b) how you can do it John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. Edited 2 time(s). Last edit at 09/21/2015 09:35PM by john vanlandingham. |

There is plenty of work that goes into mounting any diff that's not factory. The mk3 supra diff is pretty straight forward, and I think it would make a great senior project for HS. The diff/CV adapters are simple simple to make, and I'm sure John wouldn't mind sharing the thickness if you can't measure the difference in flange widths (which is incredibly easy by the way). It would also give you a diff that works WELL, and is extremely overbuilt (a good thing). Other than the CV adapters, you'd be doing the same work (diff mounting points, getting pinion angle and height set correctly). This would be a 1-2 day CAD project for an experienced engineer or draftsman. You have a few terms to work on this, it shouldn't be a problem. |

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

Conner, thought about this some after a whole lotta face-palming..

The CV adaptors are the EASIEST thing in the whole process... 2 bolt circles Now I make them this shape because its easy and for me in production enviroment cheap. If fact those "cookies" are cheaper to do that way----it is a flame cut deal that is cheaper than what some steel suppliers wanted to charge for the saw cutting operation (they quoted $1 per inch or cut PLUS the steel as BAR--ie solid bar) ... They come as raw parts with the star shaped done and a hole in the middle very close to finished size.. So for me its easy. To cut the step is kinda annoying--its called "an interrupted cut" and is noisy and a bit hard on the tip of the cutting insert but that's OK with the lathe i use. BUT! Nothing says the adaptors must be star shaped...They can be round, so a quick zip on the od, bore a big hole in the middle if you want, cut the step --making sure there's wrench clearance- and then over to the mill to bang in the bolt circles and tap the CV ones---very very easy.. Now in a learning situation the best way to learn is with good clear accurate criticism... Somebody saying "DOoooooOOOOD! your schtooopid" doesn't help. But saying "There's clearly a poor grasp of what skills and requirements in your thinking because---> this is the important bit<-------- you think the easy part is hard and you say " I'd have to design and make CV adapters, and right now i just don't feel like I have the skill level/resources to do that. " But they're the EASY part.. ALL the other parts are far far more difficult to get spot on.... Each round of these I've revised the fixtures and jigs and am re-doing the rear mount again... The CV adaptors are so easy that it shouldn't qualify as a "project"---and that's one reason i suggested choosing some other things above.. Whatever the case, I can send you the CV thangs, and loose parts to do the rest of the diff mount so it looks like a project. (Kinda why I like the star shape: it looks like a part) You could learn a lot more attacking all those other things and if the point is to learn then its a little different than what the point otherwise is---which is driving a "pretty damn good car down a gravel road well" Truth is I look at the whole rally thing as primarily a learning exercise...And then again I look at life as a on-going, never ending learning exercise in a general way.. Its just as the situation demands it I say we need to shift from a "wide angle shot" to a zoom in "close up" now on say driving techniques, now on engine build for relaibility, now on engine performance, now on gearbox function, now on whatever it is for the moment---then zoom out back to the general "wide angle shot"---always remembering what the "main point is" and thats driving down a gravel road.. There's a nice little anthropology book which illustrates this idea called "The Anthropological Lens: Harsh light, Soft focus" The Anthropological Lens: Harsh Light, Soft Focus, 156 pages, 0521004594, 9780521004596, James L. Peacock DOWNLOAD http://bit.ly/1oU3mc3 http://www.alibris.co.uk/booksearch?browse=0&keyword=The+Anthropological+Lens%3A+Harsh+Light%2C+Soft+Focus&mtype=B&hs.x=19&hs.y=26&hs=Submit

What's the connection between anthropology and rally car building and driving? Both are complex and dynamic and changing subjects and a methodology that helps understanding complex concepts and ideas helps period.. What I'm suggesting is that YOUR approach--how you view the complex problem is the central thing..And from my point of view, there's little difference between how we "approch" life, choosing a car, choosing the mods we choose, choosing the value of where we spend our limited money and time, choosing how we try to drive... In other words school and project you choose are part of a whole. i could go on but I have to pack some parts and then zoom to machine shop with a Xratty block for 1) surfacing the deck and quick hone and a good washing. John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. |

NoCoast Grant Hughes Super Moderator Location: Whitefish, MT Join Date: 01/11/2006 Age: Midlife Crisis Posts: 6,818 Rally Car: BMW |

|

John, what are you changing up on the rear mounts? I'm at a great point on Dave's XR to modify it. I also have a few ideas I'd like to bounce of ya that would hopefully make it more adjustable and easier to remove/install. When are you free for a ring? |

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

No. Just had a cuppa tea and I haz ciggies. John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. |

Gravity Fed Alex Staidle Mod Moderator Location: Δx = ħ/2Δp Join Date: 08/21/2009 Age: Settling Down Posts: 1,719 Rally Car: Various Heaps |

as a chemistry guy, i vote mixing toluene to find how much boost you can REALLY run...

First Rally: 2010 First RallyX: 2004 (a bunch) Driver (0), Co-Driver (7) Organizer (3), Volunteer (3) Cars Built (2.5), Engines Blown (2) Cages Built (0) # of rotations (3.5) Last Updated, Apr 9, 2023 |

cmanreinhart Conner Reinhart Godlike Moderator Location: Livonia MI Join Date: 03/18/2014 Age: Party Animal Posts: 28 Rally Car: 1987 xr4ti |

First off thanks for all the pictures and in-depth detail John I really appreciate it! And after thinking about what you guys said some more.... Yeah I could figure out how to design and make the CV adapters. But I guess what I meant to say when I said: " I'd have to design and make CV adapters, and right now i just don't feel like I have the skill level/resources to do that. " is that once I design the CV adapters I won't be able to fabricate those my self, I'd have to send them to a machine shop to be made (since I don't have a big enough lathe). Not a big deal its just I kind off wanted to fab up and do everything myself.... Which Is why I was leaning towards the BMW diff since I'd be able to fabricate all the stuff needed for it in house. Oh and I think someone mentioned this earlier but when I do a Supra Diff swap would I have to shorten the driveshaft at all? Or swap out the flange on the driveshaft that mounts up to the diff? Only reason I'm asking is because when I was doing some research I read somewhere that a guy didn't even have to play with the driveshaft (i.e shortening it/messing with the mounting flange) at all. And the deciding factor lately between the two diffs is that I cant even find a 4.30 lsd supra diff near me, let alone for cheap. I've actually found more BMW diffs which is really why I took it into consideration in the first place. -Thanks, Conner Edited 2 time(s). Last edit at 09/23/2015 02:27PM by cmanreinhart. |

Conner, the adapters from JVAB cost very little in the grand scheme of things. Maybe $150 for the set, on the high end... but I honestly have no idea. The Supra diffs can be had for $100, and the AWESOME Weir upgraded shim kit $75. Just so you know. Design your own adapters, and if you can't get them made/sponsored (it IS for education... tax write off) then you can order some from John... Did I really just say that? What about taking on measuring the rear end of the XR and making a nice, CONSTRAINED (creating a "skeleton" with planes, points, and a few sketches to locate it all) CAD model? Then you'll need a nice and accurate model of the rear diff so you can locate it properly. Then you can place whatever diff you want in there and just line it up, connect the dots with the mounts, and your good to go. You could even add in the suspension pickup points if you really wanted to get fancy. I cannot stress how important it is to have a constrained skeleton before starting your CAD work. If you have any questions, just ask away. Edited 1 time(s). Last edit at 09/23/2015 06:38PM by Robert Culbertson. |

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

Yeah Conner, Culbertson and i were talking about this and we came up with the idea of a good CAD drawing of the standard underside of car, standard beam, trailing arms diff mounting and of course the inside of the car...Once you---er uhm "we" have a drawing then you can think about "designing" things by drawing them and floating them around..

THAT process --which is a fundamental thing, is worth getting down... Engineering is not 'just winging it" John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. |

NoCoast Grant Hughes Super Moderator Location: Whitefish, MT Join Date: 01/11/2006 Age: Midlife Crisis Posts: 6,818 Rally Car: BMW |

|

Shoot the underside of your XR and send it my way! That's way easier than measuring from the ground with a bunch of straight edges and levels. My work just picked up a new super duper Faro arm, way better resolution than the last one. Software still is a pain to use, and transferring files to CAD is not seamless. |

NoCoast Grant Hughes Super Moderator Location: Whitefish, MT Join Date: 01/11/2006 Age: Midlife Crisis Posts: 6,818 Rally Car: BMW |

I got rid of my XR a few months ago!

We used the Faro to scan, design, and build the Subaru GC weld on strut plates. Simple design to do by hand but an easy one with scanner. Oh, and cage feet we've used it for. Too big and cumbersome for whole car. We have an E46 coming in a few weeks for cage that we will be scanning entire interior and using that to model the basic cage structure and cage feet. My Tuesday pipe dream contribution is a tube frame buggy that uses all Subaru crossmembers and suspension pickups. Of course, my second thing is a full scale wood model for hammerforming an aluminum body. We also have a crossover for our rallysprint course at CORE on there, though that one is more realistic and we've already found a potential cheap source of the tunnel, handy knowing a bunch of civil engineers. Grant Hughes |

cmanreinhart Conner Reinhart Godlike Moderator Location: Livonia MI Join Date: 03/18/2014 Age: Party Animal Posts: 28 Rally Car: 1987 xr4ti |

Alright so I found a Supra diff that comes with a set of 3.73, 3.90, 4.30 gears along with the diff housing/carrier and the LSD unit for $250 does that sound like a good dealto you guys?? Only catch is that I'd have to rebuild diff since none of the gears are installed yet on the LSD. And I'm yet to find a rebuild kit for a "MK3 supra diff" anywhere out on the interweb... Any suggestions where to look or to buy a rebuild kit?

Oh and after doing some more reading on the e36 3.91 LSD they on receive/get 20% lock up.... So I figure if I'm going to bother doing a swap I mys well do it right and with a diff that actually locks up. Unless I can find a cheap open one for like $50 and then I can just weld it. Thanks, Conner |

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

More Toyota info than you could ever want here. http://www.gearinstalls.com/ TONS of very detailed info... You could get that diff and sell off the other ratios you don't use. 4.3 is the keeper. You could make millions! We'll all be fabulously wealthy---cause you are gonna share, aren't ya? John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. |

Sorry, only registered users may post in this forum.

Rally Anarchy © 2014 Corvus Digital –

Part of the AutoShrine Network –

Problems? Send an email to the Webmaster