Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Steve, tank is vented to atmosphere. "full" oil level is above pump (no lift once primed), but the little "hoop" valve over the pump stops gravity force feeding the pump to overfill the sump while parked (worked for a year...

) Hydraulic lifters? what is this tech you talk of? ) Hydraulic lifters? what is this tech you talk of?

Pete, that was the reason for setting up the relief into the return from the tank (under suction)... essentially dumping back into the sump as per SBC pump standards... Okay, food to chew on. More testing coming. Sub $100 dry sump FTMFW

Cheers Edited 1 time(s). Last edit at 07/27/2016 10:58PM by Mad Matt F. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Okay... So the long year of theorising, pontificating, reasoning, self-doubting at a distance meh... Bu wahh haa haa haa Yeah baby... All's well that gets oiled well...

I had an hour tonight to play, and thinking about the issue, was prepared to move the tank closer to reduce the suction load... with the prospect of potentially uprating the suction line, however. I used 1/2" hard line from the reservoir to the pressure pump, but there was one bend I did in the "oil cooler hose".... well yeah, oil cooler hose is meant to work under pressure, yeah... um... Not under suction. That 4" - 70 degree bend was collapsing under higher suction load, probably even collapsing near idle. I changed it out to a hard line and BOOM. Pressure relief works, dumps oil, I have 44-50 lbs of idle pressure, and just a touch of the pedal gives me 70, then 70 all the way to whatever... Couple of questions though. The pontification continues

The oil out of the relief valve ( I dumped it into a container for a moment) was very foamy. I have never seen oil out of a pump, I imagine a bit of foaming, but how much? Also, so now that I've created a monster... does checking the bearing wear become a routine issue? Before bearing wear was indicated by falling pressure... now I can pump oil till there's no bearing left  I'm sure I'll still hear a knock if there's a problem, but should I be pulling the pan and checking wear in the next couple of tests? Or am I just being silly... pumping a full load of oil, there should now never be a problem? I'm sure I'll still hear a knock if there's a problem, but should I be pulling the pan and checking wear in the next couple of tests? Or am I just being silly... pumping a full load of oil, there should now never be a problem?

Cheers! Giggly giggly... |

john vanlandingham John Vanlandingham Mod Moderator Location: Ford Asylum, Sleezattle, WA Join Date: 12/20/2005 Age: Fossilized Posts: 14,152 Rally Car: Saab 96 V4 |

There's IS a reason why dry sump pil tanks are made the way they're made: de-aeration OH! What's this? An Escort dry sump tank!

See the angled entrance of that hose? Done to swirl it around the sides..Then you draw off oil off the bottom.. Same thing smrater-er guys do the rad "over-flow" bottles : frothy on top, fluid off the bottom.. Hope this make sense...Its OLD technology and its been done since before the Inter-net so it's obviously outdated. John Vanlandingham Sleezattle, WA, USA Vive le Prole-le-ralliat www.rallyrace.net/jvab CALL +1 206 431-9696 Remember! Pacific Standard Time is 3 hours behind Eastern Standard Time. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Duuuuddzzze.

Mais oui! Je suivre le guide avec la foi... Here

Doesn't show well, but the top is "in" and that tube makes a curve to get the oil spinnin'... I think maybe more oil in the tank is needed too. Only running about 1/2 capacity maintenant. Maybe I'll get a pick of "foamy oil" I mean... I'm the nervous ninny. |

mekilljoydammit Senior Moderator Join Date: 09/22/2010 Age: Midlife Crisis Posts: 336 Rally Car: No rally car yet |

From bench-running some oil stuff, yeah, it aerates like a bitch. Pretty much every time oil goes from high to low pressure, air wants to come out of suspension and foam crap up, but almost nobody ever sees it.

http://i.imgur.com/pcicdnZ.jpg http://i.imgur.com/gV82Qfu.jpg Couple pictures I took once when bench-running an oil pump on a rotary to make everything was working right - all that oil in the pan was nice and transparent before I was running the drill to drive the pump, and you can see the foamy oil returning to the pan down the front of the engine. And that's with brand new oil and not even with the engine running or anything. Real deal expensive dry sump tanks incorporate a lot of baffles; check out http://aviaid.com/shopsite_sc/store/html/dry-sump-tanks.html which has some nice cutaways. The point is kinda to both swirl the oil around and try to centrifuge the air out, but also make it bonk off a lot of surfaces to give it more time for the air to come out. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Those pics look like what I was seeing. That makes me feel better! Thanks! |

mekilljoydammit Senior Moderator Join Date: 09/22/2010 Age: Midlife Crisis Posts: 336 Rally Car: No rally car yet |

Those pics look like what I was seeing. That makes me feel better! Thanks![/quote] Yeah; though it shouldn't look like that by the time it gets to the pump inlet. Speaking as a guy who worked in one of the world's top R&D labs for fluid film bearings (ok, granted, there's not a hell of a lot of them) for a couple years I feel pretty confident in saying that bearings work better if you feed them more oil and less air. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

So I's not an in-ju-neer.... nows I realize whys theys charge the big buxk for dem oil pumpy thingys...

So my first attempt at driving Monster Oil Justy in anger today was a failure... because global warming has made it's mark, and dead of winter in Ottawa is +5 C... Don't fawk with me Oil Sand Burners... we're doing this.

Anyway... we didn't run, but I drove the beast around the lot pushing 100 lbs of oil pressure and contributing to the rise in global temps through particulate matter dispersal via quasi burned oil on the exhaust from the leaking medley of small block chivy pumps I have cobbled together... Turns out you need some clearance for a relief valve to work... and the valve jammed... I will win.  Edited 1 time(s). Last edit at 01/22/2017 10:44PM by Mad Matt F. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

okay...

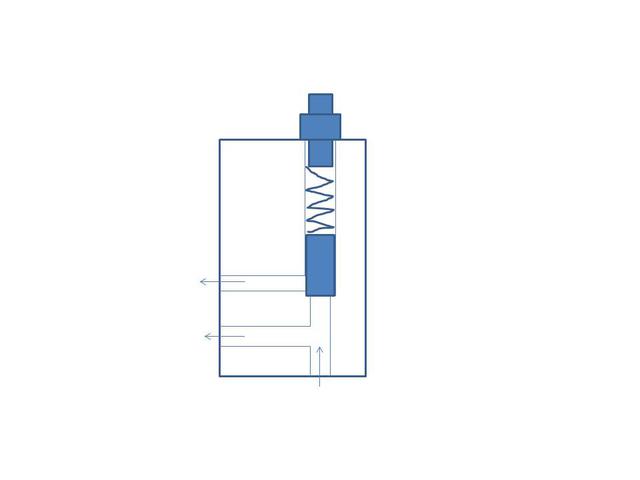

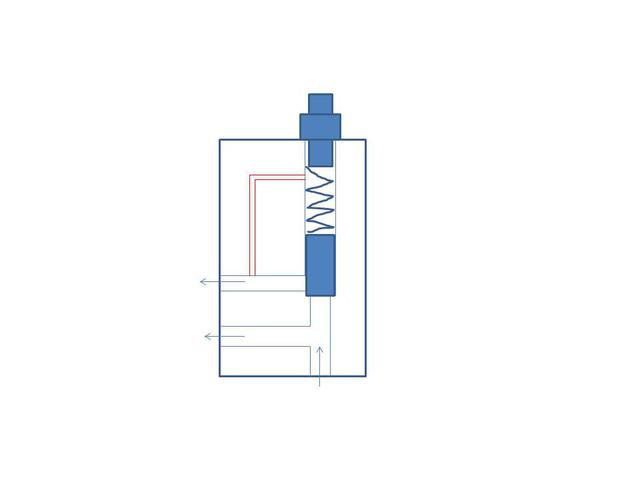

Much thinking... when I made the oil relief the fit on the piston/shuttle was "nice" moved easily, but certainly not loose. (See "oil relief 1", for the schematic drawn in this awesome CAD program called, yeah ... powerpoint, argh, and a poor photo of the set-up with the valve being in the chunk of aluminium) Last night when I pulled it apart it was "jammed" I had to tap it out with a hammer, not a BFH, but you know tap tap tap... So what happened? Oil smoodge? So I need to clearance that, but then I thought... "Man if oil gets by the shuttle, then it will fluid lock it from behind." So I need to provide an out for the oil if it goes around the shuttle. I would prefer to not dump it on the block, so can I do as following (See oil relief 2). Will that work? or will that just equalise and it wont move? I mean pressure being equal everywhere? or am I over/underthinking? Thanks!  Edited 1 time(s). Last edit at 01/23/2017 09:50AM by Mad Matt F. |

Martin Loveridge Martin Loveridge Godlike Moderator Location: Ingersoll, Ontario, Canada Join Date: 09/11/2010 Age: Fossilized Posts: 9 |

Two things that come to mind.

The plunger needs to be at least 3x the diameter to help prevent binding by cocking to one side. A decent chamfer or better a radius on the ends will help as well. Second, as drawn the vent pipe to the spring cavity will fill with oil when the relief valve opens and there is some backpressure in the drain line. The backpressure might also alter your relief valve dynamic operating point by exerting that backpressure on the top of the plunger. Route the drain back to the block someplace separately. Need a club membership? |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Martin! How are you?

Thanks for chiming in. The valve uses the stock Melling plunger, and the stock "dimensions" of the valve assembly. I only have a cheap caliper, and a selection of drill bits, so the bore of the hole might be the issue... The chamfer is pretty good, but maybe more. I'm thinking I'm going to chuck it in the drill press and just run some fine paper on it a bit... just for a bit more clearance. Yes, this is my concern, I guess the relief gallery "should" be at a lower pressure then then main gallery, but how much? and will that be an issue. Yes, I guess I could plumb it back with a small line to the sump. Man, too many hoses! I think I might try to the relief gallery and see what happens, then I always plug that and add a line to somewhere else. Re membership, yes, I should renew! Not sure if we'll run anything this year, but Lanark sounds fun! |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

found this.

http://hydraulicspneumatics.com/site-files/hydraulicspneumatics.com/files/uploads/2012/11/PressControlValveFig2.jpg here http://hydraulicspneumatics.com/200/TechZone/HydraulicValves/Article/False/6411/TechZone-HydraulicValves Going to try it, and if it's all wonky I can replumb it elsewhere. |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

It WORKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Dang! So I drilled out a vent from above the plugger to the relief passage. Lapped the pump housing faces and used a thin paper gasket with grey silicone. Held up to 120 psi of air over oil... so thought I'd try it out again. Went out to a MCO snowcross today. Well, the last hour or so. Still had to put the pump in this morning and test it yadda, drive 2.5 hours... yadda.. got 3 runs in plus some puttering around the place. Steady Eddie at 55 lbs. I might up it a bit? But happy to report it seems to function. More testing, and Lanark? |

Mad Matt F Matt Follett Godlike Moderator Location: La Belle Province, Montreal Join Date: 03/13/2006 Age: Possibly Wise Posts: 646 Rally Car: Don't Laugh, the Justy is Fun! |

Okay, so now I have an engine question...

Justy's stock redline is 6000 rpm. In stock form, I always felt it fell flat at 5500, and would rarely exceed that since it seemed to be a waste. Now, with all the changes (cam, header, carbs, compression; stock bottom end), it makes power past 7000! Before the drysump I was trying to be careful and not spin it too fast, although often found myself creeping towards the 6500 mark. Yesterday, in part due to experimentation, and in part due to the wonderful sound... I was running up to 7000 maybe a bit more

I understand having the valve-train fly apart is one issue, but if the motor "seems happy", shall I continue to reach for the limits? Do I just paint the tach numbers white?

|

mekilljoydammit Senior Moderator Join Date: 09/22/2010 Age: Midlife Crisis Posts: 336 Rally Car: No rally car yet |

|

Sorry, only registered users may post in this forum.

Rally Anarchy © 2014 Corvus Digital –

Part of the AutoShrine Network –

Problems? Send an email to the Webmaster